At Helix Precision we take pride in our productivity and efficiency in all areas. We invest in brand-new equipment from the leading manufacturers in the business so that we always have the latest and most cost efficient technology available to our customers

Capabilities

Each job that we process we access to determine the most efficient and lowest cost method of producing that particular part or assembly. An important factor in this is matching the job to the machines. Of special note is that all of our CNC Machining Centers are linked back to the main server so we can continuously retrieve data to ensure we are operating at peak efficiency and are staying on plan at all times.

Additionally all CNC programs are transferred into the machines from Cimco NC Base on the computer which is located right next to the machine. All of these things add up to processing your parts with the highest level of quality at the lowest possible cost! Following is a brief overview of our capabilities.

People

Any discussion of capabilities has to begin with our people. At Helix Precision we are very fortunate to have a group of talented, hard-working people who are fully committed to the company as well as to providing our customers with the highest quality product available. We are immensely proud of our people!

CNC Turning

From small compact-sized, high-speed technology, to multi-task machines with milling and drilling capability (that finishes all machining stages with fewer set-ups) to larger turning capacity up to 15” Dia x 600mm length we have a good selection of Turning centres to service most company’s needs in this area. All our Lathes are equipped with Edgecam Ultimate Turning Cam Facility for programming with maximum efficiency. Our high-performance turning centres include numerous high-productivity options including Driven Tooling, parts catchers, tailstocks, and tool Pre-setters – all of which allow us to offer our customers an excellent service. See Plant list for full details

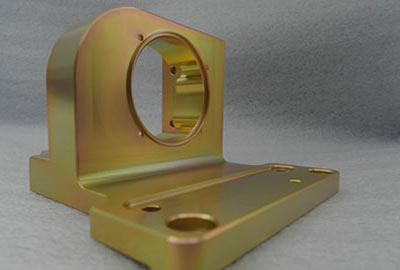

CNC Milling

Helix Precision provide a comprehensive and high-quality CNC milling service from a combined factory area of 8000Sq Ft. at our specialist machining facility in Hull, UK.

We have a range of milling machines from high speed smaller machines suited to complex aluminium parts to heavy duty BT50 large horsepower machines well accustomed to cutting Exotics such as Inconel, Titanium and similar materials. We are also Aerospace AS9100 accredited so when it comes to the production of specialist aerospace components in small to medium sized batches, we understand that you need the flexibility that only a company with proven expertise and outstanding commitment to quality can provide. This is where the team at Helix Precision excel and stand out from our competitors.

We can handle parts up to 1300mm x 650mm in size and can produce complex CNC milled parts to a high level of accuracy with fast turnaround.

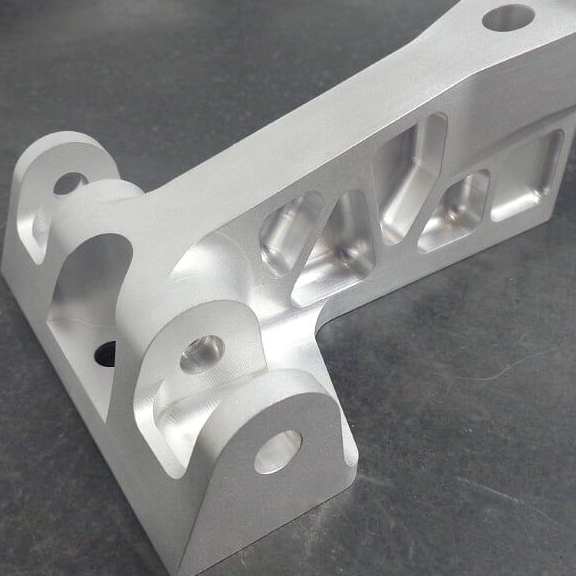

5 Axis Milling

Helix offers 5 axis milling for today’s ever increasing demand for more complex parts we have invested in a Lehmann trunnion table and the latest workholding technology with Lang Makrogrip vices and the Zero point clamp system for maximum efficency the ultimate solution for machining accurate and complex components. Can helix make your parts more economical and more precise by minimising setups and machining 5 faces in one hit? See Plant list for full details

Assembly

We have a very well equipped and skilled assembly department. From installing precision threaded inserts to complete assemblies or sub-assemblies, Helix Precision has the skill and experience to handle your assembly needs. Our assembly department includes clean, well-organised and lighted assembly area. Approximately 20% of the projects we receive include some sort of assembly.

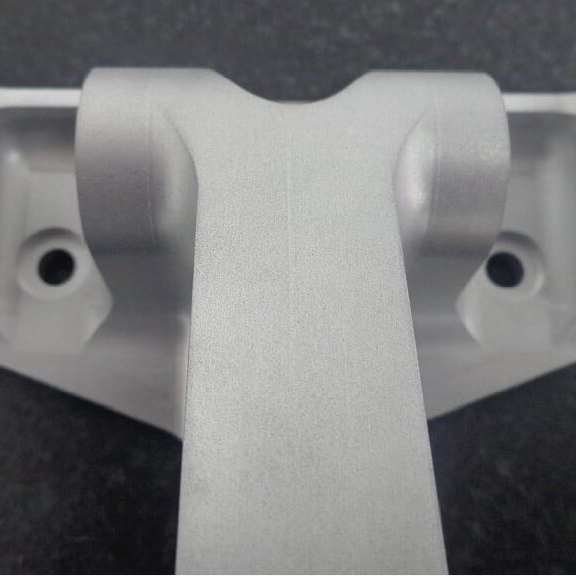

Vapour/Wet Blasting

We offer Vapour Blasting in house on parts we machine, customers often request this as it is an excellent surface conditioning pre-treatment prior to anodising and painting along with many others.

Kanban/kitting

We offer an assembly and Kanban stocking service for clients in a range of industries that require there supply chain to operate in this way.

With our Factory Master MRP System we can stock parts and have auto works orders replenish stocks based on pre-determined Min-Max parameters, this gives you parts “just in time” and allows you to reduce inventory levels, respond to demand quicker and dramatically reduce lead times.

Kitting:

The process of kitting is used by manufacturing companies as a way of reducing material handling, processing times and improving side line assembly. Individual components are gathered together and issued at the point of use, also reducing motion time by operators and machine downtime as a result of immediate parts availability.

Packing/Dispatch

We understand at Helix the importance of packing the goods we make to a very high standard to ensure they reach the customer in the same condition we sent them, for some companies the packaging and dispatch element of the job can be a mere after thought and as a result all your hard work on the machines can be undone by parts been damaged in transit. We employ experienced personnel in this area who are well aware of the requirements and we have managed to ship parts as far as Australia without issue so rest assured Packing and Dispatch is high on Helix’s priority list!

Sub Con Services